Tandon floppy drives were used in

IBM (International Business Machine) PC/XT personal computers

in the

early 80s. The floppy disk drives were 5.25" in full height.

Initially, the single-sided, double-density versions were used in the

earlier versions of PC/XT. Shortly later, all the PCs were

shipped in newer the double-sided, double-density versions. Both

versions shared the same mechanical parts. The full height size drive

quickly became obsolete by the mid-80s and was replaced by a newer

half-height version. Tandon floppy drives were used in

IBM (International Business Machine) PC/XT personal computers

in the

early 80s. The floppy disk drives were 5.25" in full height.

Initially, the single-sided, double-density versions were used in the

earlier versions of PC/XT. Shortly later, all the PCs were

shipped in newer the double-sided, double-density versions. Both

versions shared the same mechanical parts. The full height size drive

quickly became obsolete by the mid-80s and was replaced by a newer

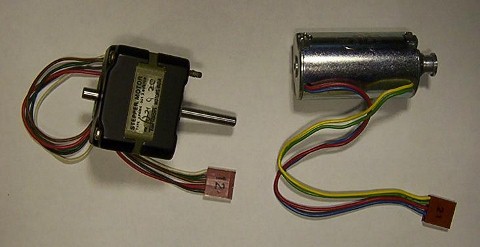

half-height version.Like many other computer equipment and perpherals, this Tandon Full height floppy drive is no longer used. Thus, the drive is gently used and still contains a lot of useful machine parts, such as the motors and the ball bearings. Some other electronic parts includes the connectors, micro-switches, LEDs, etc. The drive is taken apart and useful parts can be recovered. As reusing an old, discontinued product, when the products become obsolete and after many years, Some of the parts used to make them will be discontinued. So most of time, finding the specificications for those spare parts can be a problem. But without any information about the specification, to use these parts building some hobby projects, such as the robots will be difficult. First off, there are two motors in the disk drive. Application of these two motors will be very useful in making robotic hobbies / projects. Finding the wirings of a DC motor and stepper motor is very simple. To find the polarity of the wirings on the DC motor, the coil wirings, and the phase sequence in the stepper motor, you need to know the maximum rated voltage of the motors. The maximum can be estimated by the size of the motor or it can be estimated from the maximum voltage and current consumption.  The floppy drive has 2 motors, a 12V unipolar stepper motor is used to move the read/write head in and out. The second one is a DC motor to spin the disk at a constant speed of 300 rpm, and it is a 12-volt permanent magnet type DC motor. Normally a DC motor has only 2 wires, but this DC motor has 4 wires. The motor only needs 2 wires for the 12V power supply input. The other 2 wires are the outputs of built in encoder. It is a magnetic type speed encoder, and it generates sine wave output signals. The frequency and amplitude is directly proportional to the rotating speed. The wire colour code pinout of the DC motor:

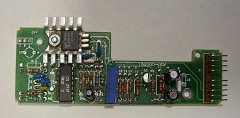

The same type of DC motor was also be used in Shugart SA400 5.25" single-sided floppy drives. The Shugart floppy drives were used in many made personal computers in the 70s to the early 80s. Apple Computers Inc. made the Apple II+ and Apple IIe in the late 70s and early 80s, which also used the floppy drive for single-sided, double-density floppy disks. The Apple II series computers used the mechancial portions, but they had their own design in their electronics.   The motor speed controller is mounted at the

back of the floppy drive. The design of the speed controller is using a

CS2917, frequency to voltage converter. The equivalent part, LM2917, is

made by National Semiconductors. It can be seen uses in some assembly

boards. The motor speed controller is mounted at the

back of the floppy drive. The design of the speed controller is using a

CS2917, frequency to voltage converter. The equivalent part, LM2917, is

made by National Semiconductors. It can be seen uses in some assembly

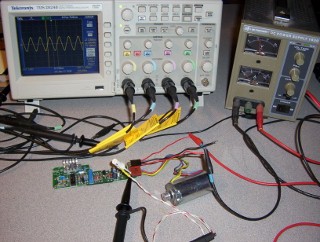

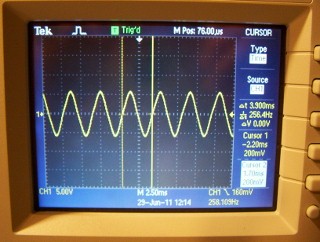

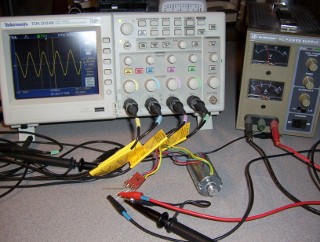

boards. The CS2917 senses the frequency output from the internal motor encoder. The frequency converts to a voltage and drives the Darlington transistor control to the voltage output level to the motor power supply terminals. Thus controlling the speed of the motor. The connector pinout of the motor speed controller: 1 - encoder input 1 2 - encoder input 2 3 - motor V+ 4 - motor V- 5 - no connection 6 - no connection 7 - ON/OFF control, motor ON connect to ground, motor OFF connect to 5V 8 - no connection 9 - power supply ground 10 - +12 volt power supply input   The oscilloscope probes the terminals of the encoder and shows the sine waves output. The speed controller is calibrated at the disk spinning speed of 300 rpm, and the ratio of the two pulleys is 1:6.65. The output signal is calculated as 8 cycles/revolution.  To test the maximum motor speed without connecting to the speed controller, the motor is directly connected to a 12V power suppy. The no load test result is 7200 rpm at 12V 400 mA. The stall current is about 1.8A. The Tandon floppy drive uses a 12V 5-wire unipolar stepper motor to move the read/write head in and out. It is marked on the motor of 3.6o per step. Finding the stepper motor wiring and phase sequence can be found here: click here. The wiring colour as follows:

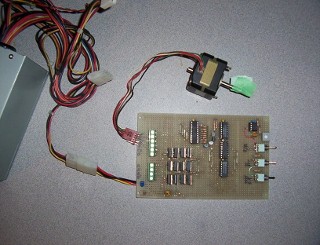

The rotating direction depends on the pulsing of the phase sequence. From the wiring colour code as above, the phase's pulsing sequence of A-B-A'-B' is spinning clockwise direction. When reversing the sequence, it will rotate at a counter-clockwise direction.  Testing the Tandon unipolar stepper motor, the details to make the stepper motor tester and download schematic. click here External links: IBM Personal Computers Shugart SA400 floppy drive |