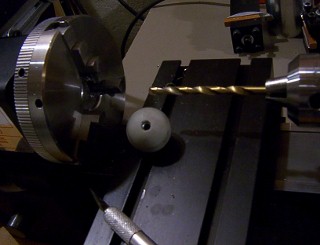

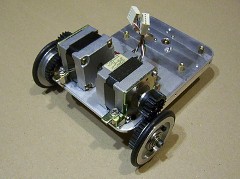

There are many useful parts in a PC computer equipment, such as floppy drives, hard drives, printers, and etc. These mechanical parts can be used for projects and experiments. Most of the components are removed from the equipment that still function. Many of the parts will not fit well completely in the project, but most of them can be easily modified.

In this project, to build a 3-wheel robot, the parts and materials are collected for suitable dimensions and shapes so that they can be modified according to the project design. I have salvaged a lot of parts from computer equipment to build a robot.

Loading ....

|

View larger image |

|