Move

the saddle to the

right at the end of the lead screw. Loosen the screws and detach the

apron from the saddle. Remove the apron from lead screw.

Move

the saddle to the

right at the end of the lead screw. Loosen the screws and detach the

apron from the saddle. Remove the apron from lead screw. | The

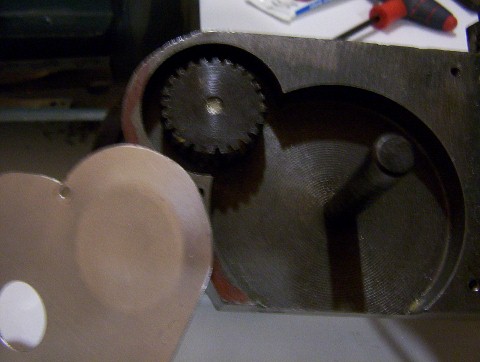

handwheel

gear

and the pinion gear are exposed, so chips and debris will get

into the apron gear housing, and stick on the greese. Sadly, it cannot

be

cleaned. To tackle this issue, I came up with my version of a chip

guard by using a piece of

aluminum sheet metal to protect the gears. Here are the steps to modify the chip guard: |

Move

the saddle to the

right at the end of the lead screw. Loosen the screws and detach the

apron from the saddle. Remove the apron from lead screw. Move

the saddle to the

right at the end of the lead screw. Loosen the screws and detach the

apron from the saddle. Remove the apron from lead screw. |

Use a piece of AWG 19

gauge (0.036" thick) aluminum sheet (thinner material will be

easier to work with). Use a piece of AWG 19

gauge (0.036" thick) aluminum sheet (thinner material will be

easier to work with). First to make a hole slightly larger than the diameter of the pinion gear, then cut the aluminum sheet along the shape of the apron. Drill three 0.125" holes on the plate; the drill holes must be on the wall of the apron for mounting screws. |

The

handwheel gear is

higher than the wall of the apron. When the chip guard is mounted on

the wall, it will interfere with the gear. Use a piece of 1.125" round

steel rod to make a 0.1" deep depression on the plate. The

handwheel gear is

higher than the wall of the apron. When the chip guard is mounted on

the wall, it will interfere with the gear. Use a piece of 1.125" round

steel rod to make a 0.1" deep depression on the plate. |

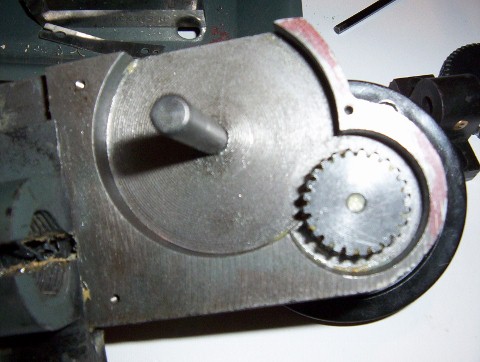

Use the

holes on the chip guard

plate as a

template to drill and tap three

#4-40 holes on the wall of the apron. Use the

holes on the chip guard

plate as a

template to drill and tap three

#4-40 holes on the wall of the apron. |

The finished chip guard is

mounted on the apron. The finished chip guard is

mounted on the apron. |