This rotary headstock is made for mounting Dremel rotary tool models of 100 and 200. The model 100 is a single speed version that has 0 and 30,000 rpm only. The model 200 is a variable speed version adjustable from 0 to 30,000 rpm.

The Dremel rotary tool is a precision tool primarily applied to woodworking. It is designed as a light, versatile duty power tool. The model 100 and 200 are the two very early models. The latest rotary models do not fit into this headstock holder because of the different body dimensions. The nose housing cap thread is 3/4"-12 TPI (standard thread size for all models). This will be compatible with all others optional adapters.

The Dermel rotary tool bits provide a larger variety of applications, it is not limited for woodworking. Various applications include: metal cutting, grinding, and even ceramic tile cutting. It provides a lot of cutting bits in large areas of applications.

This dremel rotary tool headstock can be mounted on the models 100 and 200, as shown in the picture of the Dremel model 100 (single speed) - and the Sears Craftsman model # 572-243502, which is same as the Dremel 200 variable speed version (the Craftsman rotary tools is OEM made by Dremel). Both ot them can provide 0 to 30,000 rpm high speed operation.

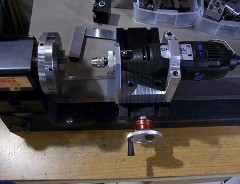

The rotary tool holder is mounted on the Sherline mini-milling machine for milling and drilling operations. The pictures show the holder mounted on the lathe tables. When it is mounted on the lathe cross slide table, the spacer block will be use for raising up the lathe headstock to align the spindle center and the rotary tool. It is very useful for grinding and cutting small diameter round stocks.

In this picture, the holder is mounted with the variable speed rotary tool (Dremel model 200). The variable speed is needed for working with different materials, like plastics, which requires slower speeds to avoid melting the piece.